Maintaining a safe workplace is not just an ethical obligation – it is a legal requirement under the law in England and Wales. The Health and Safety at Work etc. Act 1974 places a statutory duty on employers to protect the health, safety and welfare of their employees and others affected by their work activities. Yet despite comprehensive legislation and awareness campaigns, preventable workplace accidents remain common. In 2025, employees reported 680,000 non-fatal injuries to the Labour Force Survey. This highlights persistent challenges in recognising and managing hazards across a wide range of industries.

This guide outlines ten of the most common workplace hazards. It provides legal context about staff training and other practical steps employers can take to reduce risk, meet compliance obligations and protect their workforce and their organisation.

1. Slips, trips and falls

According to the HSE, slips, trips and falls on the same level are the most common cause of non-fatal workplace injuries in the UK. They account for around 30% of all reported incidents. These accidents are often the result of wet or uneven surfaces, poor lighting, obstructed walkways, or lack of adequate warning signage.

Under the Management of Health and Safety at Work Regulations 1999, employers must assess the risk of slips and trips and take reasonable steps to prevent them. This includes maintaining clean and dry floors, using non-slip mats in wet areas, fixing uneven flooring, installing appropriate lighting, and displaying warning signs when surfaces are wet or hazardous.

Where an employer fails to address these foreseeable risks, an injured employee may have grounds to bring an accident at work claim.

2. Fire hazards

Workplace fires are rarely due to a single failure. They often result from a combination of overlooked hazards, poor maintenance and inadequate staff training. Common culprits include overloaded plug sockets, frayed electrical cables and hot work tools such as soldering irons. But everyday items can be just as dangerous. A poorly maintained microwave in a staff kitchen or a portable heater placed next to a paper bin can present a serious risk if left unchecked.

Under the Regulatory Reform (Fire Safety) Order 2005, responsibility for fire safety rests with the ‘responsible person’ – typically the employer, owner or occupier of the premises. They must complete a written fire risk assessment, keep it up to date and act on its findings. This includes:

- Maintaining appropriate and regularly serviced firefighting equipment.

- Installing and testing alarm and detection systems.

- Keeping escape routes and final exits clear at all times.

- Training all staff in fire safety awareness and evacuation procedures.

- Conducting fire drills and displaying clear emergency instructions throughout the premises.

Compliance is not a one-off exercise. Employers must revisit fire risk assessments when the building layout changes, when they introduce new processes or equipment, or following a near miss. Ongoing reviews and consistent investment in fire safety measures are essential for legal compliance, and for protecting lives.

For more information on fire safety in the workplace, please read our article Fire safety in the workplace – A simple guide.

3. Electrical safety

Electrical faults in the workplace cause shocks, burns, fires and, in severe cases, fatalities. The Electricity at Work Regulations 1989 require all electrical systems to be maintained in a condition that prevents danger, with inspections and repairs carried out by competent individuals.

PAT Testing (also called EET)

This includes regular Portable Appliance Testing (PAT) for moveable equipment, adherence to manufacturer guidelines for safe use and immediate removal of any item showing signs of damage, overheating or malfunction. Damaged plugs, exposed wiring, scorched sockets and flickering lights should all be treated as potential hazards, not just inconveniences. Employers don’t have to outsource PAT testing. Online PAT training is an excellent way to ensure a safe working environment and reduce accidents due to faulty electrical equipment.

Only trained and qualified electricians should carry out electrical work. Employees need to know how to recognise early signs of faults and how to report concerns promptly. High-risk environments may require additional safety measures, such as residual current devices or splash-proof sockets.

Employers who neglect electrical safety – whether through skipped testing, poor reporting systems or cost-cutting on repairs – risk serious injury to staff and are exposed to both regulatory penalties and civil claims.

4. Hazardous substances

Hazardous substances in the workplace extend beyond obvious industrial chemicals. They include cleaning fluids, biological agents, and airborne particles such as wood dust, flour and silica. All of these can cause serious harm if not properly managed. Under the Control of Substances Hazardous to Health (COSHH) Regulations 2002, employers must assess the risks associated with these materials and implement effective controls to limit exposure.

This involves correct labelling, secure storage and restricting access to authorised personnel. Personal protective equipment such as gloves, respirators or goggles must be provided where appropriate. Workers must be COSHH trained, so they can safely handle, use and dispose of substances hazardous to health. In environments where inhalation risks are present, employers may need to install local exhaust ventilation systems.

Where it is not possible to eliminate long-term exposure, health surveillance may be a requirement. For example, lung function testing may be needed for workers exposed to dusts. Skin checks may be needed for those handling sensitising agents. Employers must also maintain up-to-date COSHH assessments and review them when substances or work processes change.

5. Mechanical hazards

Machinery introduces a range of physical risks in the workplace, from entanglement and crush injuries to cuts, burns, or amputations. Under the Provision and Use of Work Equipment Regulations 1998 (PUWER), employers must make sure any machinery or equipment provided for use at work is suitable, safe, properly maintained, and used only by trained and authorised personnel.

Key requirements include fitting machine guards to restrict access to dangerous moving parts, installing emergency stop mechanisms, and enforcing lockout/tagout systems during maintenance to prevent unexpected start-up. Instruction manuals must be accessible, and operating controls clearly labelled. Equipment should be inspected before each use, with any defect triggering its immediate withdrawal from service.

6. Environmental conditions

Environmental hazards in the workplace can directly contribute to accidents and occupational illness if left unmanaged. Exposure to high or low temperatures, poor air quality, inadequate lighting, and excessive noise can increase the likelihood of slips, trips, contact injuries and long-term health conditions.

The Workplace (Health, Safety and Welfare) Regulations 1992 require employers to maintain a “reasonable” indoor temperature, sufficient lighting and clean, fresh air. In practical terms, this means fitting heating or cooling systems, improving ventilation in confined spaces, and installing task lighting to reduce shadowing or glare, particularly in areas where machinery or hazardous materials are used.

In low-lit areas, the risk of trips or contact with moving parts increases. Within poorly ventilated environments, fumes, dust or heat build-up can contribute to faintness, respiratory problems or fatigue-related mistakes.

The Control of Noise at Work Regulations 2005 also impose legal duties on employers to assess and control exposure to excessive noise. Sustained, high noise levels can lead to permanent hearing damage and prevent workers from hearing alarms or warning signals, raising the risk of accidents. Where action thresholds are exceeded, employers must provide hearing protection and appropriate noise awareness training.

7. Ergonomic risks

Poor workplace ergonomics are a leading cause of musculoskeletal disorders (MSDs), including back pain, repetitive strain injuries, and upper limb disorders. These injuries often arise from sustained poor posture, repetitive movements, heavy lifting or awkward positioning.

Employers have legal duties under both the Manual Handling Operations Regulations 1992 and the Health and Safety (Display Screen Equipment) Regulations 1992 to assess and reduce these risks. In office environments, this means providing height-adjustable chairs, monitor stands, footrests, and ergonomic accessories. Users should position display screens to avoid neck strain. It is important to tailor workstations to each individual’s size, role and working pattern.

In physical jobs – such as logistics, retail, or maintenance – the focus shifts to safe lifting techniques, team lifts, job rotation, and the use of trolleys, hoists or powered tools to reduce physical strain. Employee Manual Handling training is crucial, especially lifting and carrying, to help reduce the risk of injury.

Ergonomic assessments should be completed for all employees, including new starters and those returning to work after an injury. Preventive action can reduce long-term absence, improve productivity, and reduce the risk of injury claims linked to work-related MSDs.

8. Workplace stress

Work-related stress is a health and safety issue with direct consequences for both individual health and organisational risk. According to HSE, stress, depression and anxiety now account for more than half of all work-related ill health cases in the UK.

Under the Management of Health and Safety at Work Regulations 1999, employers must assess risks to mental health in the same way they would physical hazards. The HSE’s Management Standards identify key workplace stressors. These include excessive workload, lack of control over work, inadequate managerial support, poor communication, and bullying or harassment.

When an employer fails to address these factors, the effects can include chronic fatigue, burnout, impaired concentration and increased accident risk. This is especially true in high-pressure or safety-critical roles. Stress can also worsen existing physical conditions, delay recovery from injury and contribute to long-term sickness absences.

Preventive measures include regular one-to-one meetings, systems for anonymous feedback, clear reporting routes for behavioural concerns, and access to occupational health services or mental health first aiders. Stress awareness training helps employees learn to recognise and manage stress effectively. Training empowers employees to support colleagues who are struggling with stress, thereby enhancing overall well-being and productivity. Employers should maintain and implement a formal mental health policy, regularly reviewed in line with organisational changes.

9. Vehicle-related incidents

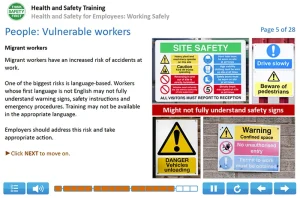

Workplace transport presents a high risk of serious injury or death – particularly in logistics, construction, manufacturing and agriculture. Forklifts, pallet trucks and delivery vans are responsible for a disproportionate share of fatal workplace accidents. HSE reports that being struck by a moving vehicle remains one of the most common causes of death at work.

To manage these risks, employers must follow HSE’s Workplace Transport Safety Guidance (HSG136), which recommends physical separation of pedestrians and vehicles, designated crossing points, clear speed limits, warning signage and one-way systems where appropriate. All drivers must be trained, assessed and authorised to operate vehicles on-site. Daily checks should be completed before vehicles are used, with defects reported and addressed immediately.

High-visibility clothing should be issued and worn in any area where vehicle movement occurs. Also, blind spots or turning areas should be monitored or fitted with mirrors, barriers or warning alarms.

Where these precautions are missing, and a worker is injured, employers may be held liable for breach of statutory duty, personal injury or, in the worst cases, corporate manslaughter. Regular risk assessments and close supervision of traffic routes are essential to reduce collision risks and prevent serious harm.

10. Inadequate training

Training failures are a common underlying cause of workplace accidents. Employees may be using equipment incorrectly, misjudging risks, or applying unsafe techniques simply because their employer did not show them how to do the job properly. Under the Health and Safety at Work etc. Act 1974, employers are legally obliged to provide employees with adequate information, instruction and training to carry out their work safely.

Training must be specific to the role and delivered at the appropriate time. Employees need training at induction, post-incident or when processes or equipment change. Common topics include manual handling training, fire safety training, first aid in the workplace training, Display Screen Equipment training, PPE usage, and risk assessments training. For roles involving hazardous machinery or substances, more detailed, competence-based instruction is required.

Supervisors also need training to identify unsafe practices and reinforce correct procedures. Documentation is essential: employers should keep detailed records of who has received training, when and on what topics. Failure to do so can leave employers exposed to legal consequences.

Preventing accidents and limiting liability

Workplace accidents often arise not from a single failure, but from a pattern of noncompliance or lack of oversight. The legal framework is clear: employers must assess risks, implement control measures and review those measures regularly. This includes:

- Conducting thorough risk assessments under the Management Regulations.

- Implementing training and supervision systems under the Health and Safety at Work Act.

- Maintaining equipment in safe working order under PUWER and the Electricity at Work Regulations.

- Managing exposure to chemicals under COSHH.

- Supporting physical and mental well-being under workplace health regulations.

Employers who fail to manage health and safety risks effectively increase the likelihood of accidents and illness. They create an unsafe working culture that can impact morale, productivity and long-term business continuity. It is essential to address hazards systematically through regular assessments, targeted training, and consistent enforcement of safety procedures. This will create a workplace where people can carry out their roles confidently and without unnecessary risk. Reducing preventable harm is not just a compliance obligation – it’s a reflection of organisational competence and care.

Looking for Health and Safety Training for Employees?

Need to comply with the Health and Safety at Work etc. Act 1974 and provide employees with adequate information, instruction and training to carry out their work safely.

Our online Health and Safety Training for Employees course provides essential knowledge to help employees work safely and confidently in any workplace.

Only £25 + VAT per person.

It covers the fundamentals of health and safety law, the responsibilities of employers and employees and the importance of reporting incidents and near misses. Learners gain a clear understanding of risk assessment, including how people identify and control hazards, the role of PPE, the use of safety signage and the importance of effective emergency planning.