Discounts Available For Bulk Purchases

| No. of total licenses |

% saving |

|---|---|

| 1 - 9 | - |

| 10 - 19 | 10% |

| 20 - 49 | 20% |

| 50 - 99 | 25% |

| 100 - 149 | 30% |

| 150 - 999 | 35% |

Manual Handling Online Training

£17.50 + £3.50 VAT

- Assured by RoSPA Qualifications

- Certified by CPD

- Audio voiceover

- Approximate course duration of 2 hours

- Downloadable certificate on completion

- 100% online training

- No time limits

This Manual Handling online course provides learners with the knowledge they need to reduce the chances of injury whilst manually handling loads in a work environment. The course outlines the 5 key principles of manual handling.

Injury to employees while handling, lifting or carrying something is one of the most common types of accident in the workplace every year. The majority of manual handling injuries last for at least three days. Many incidents cause damage to the back.

Employers must comply with the Manual Handling Operations Regulations 1992, as amended by the Health and Safety (Miscellaneous Amendments) Regulations 2002. Employers are required by law to take reasonable steps to safeguard the health and safety of all employees. This includes raising awareness about the hazards related to manual handling and outlining what can be done to minimise risk.

The approximate duration of this online training course is 2 hours.

Who needs manual handling training?

All employers need to comply with the risk assessment requirements set out in the Management of Health and Safety at Work Regulations 1999 and they need to carry out a risk assessment on manual handling tasks as specified in the Manual Handling Operations Regulations 1992.

Most employees who take our manual handling online training course work in environments where there is regular lifting. This includes retail, factory, and on-site workers, to name a few.

Reviewed and approved by lead bodies

Our Manual Handling Awareness Course has been assured by the Royal Society for the Prevention of Accidents as providing up-to-date, quality and content-approved training.

The training course also complies with the Continuing Professional Development (CPD) guidelines and is accredited by the CPD Certification Service.

Course learning outcomes

After completion of the manual handling online course, you will be able to explain the following:

- What is meant by the term manual handling.

- Health and safety regulations aimed at reducing musculoskeletal injuries in the workplace.

- How the musculoskeletal system functions

- Common musculoskeletal injuries.

- The prevalence and potential severity of handling, lifting and carrying injuries.

- The principles of relative weight increase.

- Potential risks during lifting and carrying tasks.

- Common causes of handling, lifting and carrying injuries.

- Measures for controlling manual handling risks.

- The preparation required before lifting and moving a load.

- Good and bad practice when pushing or pulling a load.

- The hazards of lifting in a restricted space.

- What is meant by psychosocial risk factors.

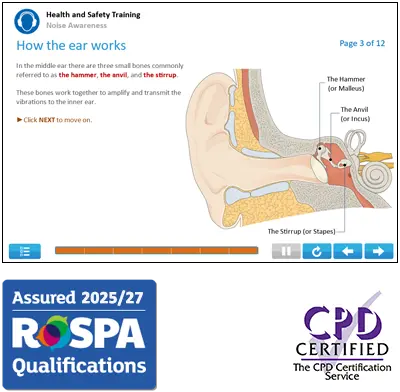

Example course pages

Below we have provided 3 examples of slides from our training course. They are designed with minimalism in mind. Our previous course participants have told us that the straightforward style makes the learning process a lot easier. Lastly, if you’d like more information on our course materials, get in contact with a member of our team.

(Click on the example screens below to view)

Course content

Our Manual Handling online training covers the following 9 topics:

1 – What is Manual Handling

The first topic is an introduction to manual handling. The topic identifies common manual handling activities and injuries. You will learn about the frequency and causes of manual handling injuries. The topic also outlines legislation that aims to reduce manual handling injuries in the workplace.

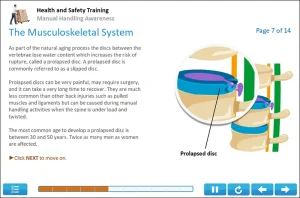

2 – The Musculoskeletal System

The second topic is about the spine, how it works and what can go wrong. You will learn about the parts of the spine and how discs absorb shock. The topic also explains the action of the facet joint and how injury can occur. It also covers the causes of musculoskeletal disorders and how to avoid them. The topic also explains what to do if you suffer a manual handling injury.

3 – Controlling the Risks

The third topic explains how to control the risk of manual handling injury. The topic also covers the most common cause of trips and falls and how to avoid them.

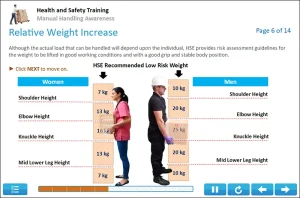

4 – Relative Weight Increase

Topic 4 outlines the factors that determine whether you can lift a load safely. You will also learn about relative weight increase and how risk changes depending on how you carry a load.

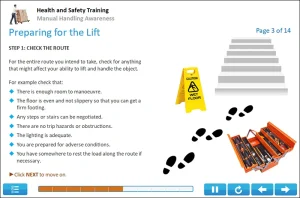

5 – Preparing for the Lift

Topic 5 is about preparation. You’ll learn how to assess the risks, check routes, and consider travel distance and height. The topic also explains when to use PPE and mechanical aids, and when to get help from another person.

6 – Lifting Technique

Topic 6 is about how to lift, carry and place a load safely. You will also learn more about common causes of manual handling injuries.

7 – Pushing and Pulling

Topic 7 is about pushing and pulling. It covers accidents caused by pulling and pushing, and how to push a load safely. You will also learn about what happens if you overload a trolley and what to do if equipment is faulty.

8 – Handling in Restricted Spaces

Topic 8 explains risk due to restricted movement and working when seated.

9 – Psychosocial or Non-Physical Risk Factors

Finally, the last topic is about psychological risk factors. Finally, you will learn about how these factors increase risk and also how to reduce that risk.

Course assessment

The assessment consists of 15 questions. The course generates an assessment from question banks so that the questions change each time a candidate takes the assessment. This makes the training suitable for initial and refresher training.

There is no limit on the number of attempts at the assessment. Unlike a lot of other training providers, at i2Comply we give candidates useful feedback so that they can learn and develop their knowledge from incorrect answers to questions.

Course certificate

When you have successfully passed the manual handling course you will be able to download and print your certificate as soon as you like.

Your certificate will include both the RoSPA and CPD logos, therefore you can use it to provide evidence for compliance.

How long is this Manual Handling online course certificate valid for?

Your Manual Handling course certificate does not include an expiry date. However, to ensure knowledge of manual handling is maintained, we recommend an employee who has previously completed the training to renew after 2 years.

In case you forget when you should be refreshing your knowledge of manual handling, the recommended renewal date will be on your certificate for reference.

Can this training course act as evidence for SSIP accreditations like CHAS, SafeContractor and ConstructionLine?

Yes, you can use our Manual Handling Awareness certificate as evidence of industry-related training. This evidence is important for SSIP accreditations. The course helps you to ensure your staff all receive appropriate training and that you have the certificates to prove it. However, each individual accreditation body will decide whether our online courses are sufficient for your company’s training requirements.

Course reviews

Do you want to see what previous candidates have to say about our Manual Handling Awareness course before buying? If so read our Manual Handling Awareness Reviews.

Previous course participants highly rate our training. Many who have successfully finished the course praise how straightforward the information is, and how easy it is to follow. We would love to hear your feedback. Please leave a review on Reviews.io or leave a review on Google.

The importance of manual handling training

Manual handling awareness training reduces the risk of manual handling injuries. It gives employees the knowledge to use correct manual handling techniques when moving loads in the workplace. Not only will manual handling training help increase employees’ awareness of risks, but employees will also recognise that that their welfare is a priority. Fewer injuries mean fewer sick days and higher productivity. So you save your organisation money when you ensure employees work safely and reduce the risk of injuries.

What workplaces need Manual Handling training?

Anywhere that staff members must lift materials manually will benefit greatly from our manual handling training course. When carrying medium to heavy loads, accidents can happen. Awareness of potential accidents can help prevention.

Many job roles require you to lift materials and stock – in a bar, restaurant, office, retail space or on a construction site. We have delivered our manual handling training to organisations, businesses and freelancers across the whole of the UK.

Start e-learning today

Getting started on our Manual Handling online course is easy – simply add the course to your basket by clicking Add to basket at the top or bottom of this page. Then view your basket and choose your method of payment.

Want to buy your course today and start it at a later date? That’s not a problem. Begin reading the slides and studying when you are ready. Our current users tell us that they buy the course and complete the studying and assessment during downtime at work, something that’s not possible with in-person training.

Health & Safety courses you may be interested in

I2Comply provides online training solutions across many different categories including fire safety, regulatory compliance, food hygiene, health & social care and more. You can view all of our online courses here.

Because you have shown interest in our Manual Handling online training, we have singled out some health and safety courses that may also be useful to your working environment:

- Abrasive Wheels Training

- Asbestos Awareness Course

- COSHH Awareness Training

- DSE Awareness Course

- First Aid in the Workplace Course

- Hand-Arm Vibration Awareness Course

- Legionella Awareness Training

- Mental Health Awareness Course

- Noise Awareness Training

- Ladder Safety Training

- Risk Assessment Training Course

- Stress in the Workplace Course

- Working at Height Course

- Working in Confined Spaces Course

Any further questions?

If you are still unsure about purchasing an online training course, it may be due to some questions yet to be answered. Our dedicated team are always on hand to offer some additional context or answer any questions you may have regarding our manual handling online course. You can contact us via phone, email or from our enquiries form here.

We also provide answers to previously asked questions in our help and knowledge base. It’s always worth having a look to see if your question has previously been answered. In this section, we’ve provided further information on certificates, licences, account settings, course details and much more.

Request an online training quote

Whether you are looking to train a small team or an entire business, we’re here to help. Let us know your online training requirements and we’ll provide you with a quote.

£17.50 + £3.50 VAT

Discounts Available For Bulk Purchases

| No. of total licenses |

% saving |

|---|---|

| 1 - 9 | - |

| 10 - 19 | 10% |

| 20 - 49 | 20% |

| 50 - 99 | 25% |

| 100 - 149 | 30% |

| 150 - 999 | 35% |